-

Phone

86-21-31261976

-

Address

No. 100, Duhui Road, Minhang District, Shanghai, China

-

E-mail

LatestProducts

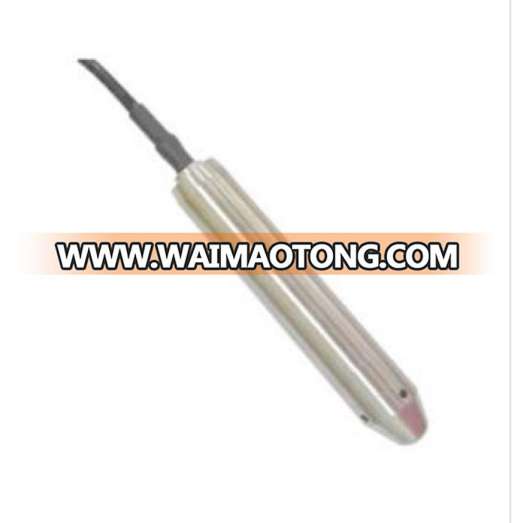

Explosion Proof Liquid Tank Level Measuring Devices

China Explosion Proof Liquid Tank Level Measuring Devices, Find details about China Pressure Transmitter, Differential Pressure Transmitter from Explosion Proof Liquid Tank Level Measuring Devices - Shanghai LEEG Instruments Co., Ltd.

Description

Basic Info

- Model NO.: SMP858-DST

- Structure Type: Monosilicon Pressure Sensor

- Accuracy Grade: 0.075g

- IP Rating: IP67

- Customized: Customized

- Field of Application: Pressure, Level, Differential Pressure, Density

- Process Temperature: -45~120ºC

- Trademark: LEEG

- Specification: Net weight: about 6.5 kg

- HS Code: 9026201090

- Type: Differential Pressure Transmitter

- Measuring Medium: Liquid

- Pressure range: 10kpa-1MPa

- Certification: CE

- Output Signal: 4-20mA, 4-20mA+Hart

- Diaphragm Material: Ss316L,Hastelloy C

- Approvals: Ex-Proof, Ce

- Transport Package: Standard Export Carton Box

- Origin: Shanghai, China

Product Description

Brief introduction

SMP858-DST diaphragm differential pressure transmitter, designed for process control and pharmaceutical industry, is suitable for CIP/SIP cleaning and sterilization. Accurate filling fluid technology eliminates effects of temperature and static pressure. Dual diaphragm overload structure, can easily cope with high overload tests.

Advantage

1.High-stability pressure sensor

Perfect match between internationally leading technology and Chinese smart manufacturing.

Establish new criteria for the optimum pressure measuring solutions.

2.Originally patented fully-sealed, fully-isolated the pressure sensor

Accurate filling fluid technology, eliminates effects of temperature and static pressure.

Dual diaphragm overload structure, can easily cope with high overload tests.

3.ASIC and SMT signal transmitting module

Powerful 24 ADC achieves high precision and quick response.

355°rotation display module, friendly button parameters operation function.

4.Strong transient voltage resistance to protect terminal module

Vigorous close protection, security guard for transmitters.

Though experiencing fulminating, it still keeps stable operation.

Features

Measuring range: 10kPa-1MPa

Output signal: 4-20mA,4~20mA/HART , customer

Reference accuracy: ±0.1% URL, optional ±0.075% URL

Media temperature: -40-120ºC,

Measuring medium:Pressure, level, differential pressure, density, interface,flow

Protection class: IP67

Power supply:4~20mA two wire,power supply: 10.5-55vdc

4~20mA+HART two wire,power supply: 16.5-55vdc

Diaphragm material: SS316L,Hastelloy C

Stability: ±0.2% URL/5years

Process connection: DN50PN10,DN80PN10,DN100PN10

Approvals: CE,MC,EX-proof certificate

Product selection

SMP858-DST diaphragm differential pressure transmitter, designed for process control and pharmaceutical industry, is suitable for CIP/SIP cleaning and sterilization. Accurate filling fluid technology eliminates effects of temperature and static pressure. Dual diaphragm overload structure, can easily cope with high overload tests.

Advantage

1.High-stability pressure sensor

Perfect match between internationally leading technology and Chinese smart manufacturing.

Establish new criteria for the optimum pressure measuring solutions.

2.Originally patented fully-sealed, fully-isolated the pressure sensor

Accurate filling fluid technology, eliminates effects of temperature and static pressure.

Dual diaphragm overload structure, can easily cope with high overload tests.

3.ASIC and SMT signal transmitting module

Powerful 24 ADC achieves high precision and quick response.

355°rotation display module, friendly button parameters operation function.

4.Strong transient voltage resistance to protect terminal module

Vigorous close protection, security guard for transmitters.

Though experiencing fulminating, it still keeps stable operation.

Features

Measuring range: 10kPa-1MPa

Output signal: 4-20mA,4~20mA/HART , customer

Reference accuracy: ±0.1% URL, optional ±0.075% URL

Media temperature: -40-120ºC,

Measuring medium:Pressure, level, differential pressure, density, interface,flow

Protection class: IP67

Power supply:4~20mA two wire,power supply: 10.5-55vdc

4~20mA+HART two wire,power supply: 16.5-55vdc

Diaphragm material: SS316L,Hastelloy C

Stability: ±0.2% URL/5years

Process connection: DN50PN10,DN80PN10,DN100PN10

Approvals: CE,MC,EX-proof certificate

Product selection

| SMP858-DST Mono-silicon differential pressure transmitter | |||||

| Item | Parameters | Code | Instruction | ||

| Model | SMP858-DST | Mono-silicon differential pressure transmitter | |||

| Sensor | Separator | - | Detailed specifications as following | ||

| Pressure range code |

S403D | 40kPa | |||

| S254D | 250kPa | ||||

| S105D | 1MPa | ||||

| Electrical connetion | Separator | - | Detailed specifications as following | ||

| Electrical connetion |

T1 | Aluminum-alloy termimal,2 cable entry M20*1.5(F), red body, white cover |

|||

| Cable entry protector |

R1 | Waterproof connector M20X1.5 one side , blind plug another side, PVC material,6-8mm diameter cable only,IP67 |

|||

| R2 | Flame proof, 1/2 NPT(F) one side, blind plug another side, stainless steel material, 6-8mm diameter cable only, IP67 |

||||

| R3 | Flame proof, M20X1.5(F) one side, blind plug another side, stainless steel material, 6-8mm diameter cable only, IP67 |

||||

| Output | Separator | - | Detailed specifications as following | ||

| Output signal | F | 4-20mA two wire, power supply: 10.5~55VDC | |||

| H | 4-20mA+HART two wire, power supply: 16.5~55VDC | ||||

| Display | A | Without LCD display | |||

| C | LCD display | ||||

| Process connection | Separator | - | Detailed specifications as following | ||

| Process connection (High-pressure side) |

Connection position | HL | High-pressure side fixed connection, low-pressure side 1/4NPT(F) ANSI/ASME B1.20.1 | ||

| /H | High-pressure side and low-pressure side both are diaphragm conection | ||||

| Connection type | G | Fixed mounting | |||

| Isolation fluid filling | S | Sillicon Oil, process temperature: -45~205ºC | |||

| H | Sillicon Oil, process temperature: 0~315ºC | ||||

| F | Sanitary fluid filling Neobee M-20, process temperature: -10~180ºC | ||||

| Wetted parts material | 4 | SUS304 | |||

| 6 | SUS316 | ||||

| Diaphragm material | S | SUS316L | |||

| H | Hastelloy C | ||||

| Flange specifications | H01 | HG/T 20592-2009, DN50PN10-PN40 raised face flange(max measuring range 4MPa) | |||

| H05 | HG/T 20592-2009, DN80PN10 raised face flange(max measuring range 1MPa) | ||||

| H06 | HG/T 20592-2009, DN100PN10 raised face flange(max measuring range 1MPa) | ||||

| Insert tube diameter | D00 | No insert tube | |||

| D01 | Diameter:66mm, length:50mm | ||||

| D02 | Diameter:66mm, length:100mm | ||||

| D03 | Diameter:66mm, length:150mm | ||||

| Process connection (Low-pressure side, diaphragm connection) |

Connection position | /L | Low-pressure side connection | ||

| Connection type | C | Capillary transmission | |||

| Capillary type | M2 | Armoured SS304L,outer diameter 3.5mm | |||

| Capillary length | XX | XX value range: 00-10,samples: 02=2 meters; 10=10meters | |||

| Isolation fluid filling | S | Sillicon Oil, process temperature: -45~205ºC | |||

| H | Sillicon Oil, process temperature: 0~315ºC | ||||

| F | Sanitary fluid filling NeobeeM-20, process temperature: -10~180ºC | ||||

| Wetted parts material | 4 | SUS304 | |||

| 6 | SUS316 | ||||

| Diaphragm material | S | SUS316 | |||

| H | Hastelloy C | ||||

| Flange specifications | H01 | HG/T 20592-2009, DN50PN10-PN40 raised face flange(max measuring range 4MPa) | |||

| H05 | HG/T 20592-2009, DN80PN10 raised face flange(max measuring range 1MPa) | ||||

| H06 | HG/T 20592-2009, DN100PN10 raised face flange(max measuring range 1MPa) | ||||

| Insert tube diameter | D00 | No insert tube | |||

| D01 | Diameter:66mm, length:50mm | ||||

| D02 | Diameter:66mm, length:100mm | ||||

| D03 | Diameter:66mm, length:150mm | ||||

| Additional options | Separator | - | Detailed specifications as following | ||

| Process connection accessory |

/A1 | T-shaped adaptor, M20*1.5(M)/ and pressure-leading tubeφ14*2*30, SUS304(low-pressure side) | |||

| /A2 | U-shaped adaptor, 1/2-14NPT(F), SUS304(low-pressure side) | ||||

| Display mode | /D1 | According to your requirement | |||

| Calibration report | /Q1 | Calibration report provided by our company | |||

| /Q2 | Calibration report provided by chinese authorised third party | ||||

| /Q3 | Static pressure report ( Differential pressure only) | ||||

| Approvals (multiple) | /E1 | Flame proof certificate, ExdIICT6, NEPSI | |||

| /I1 | Intrinsic safety certificate, ExiaIICT4, NEPSI | ||||

| /L3 | CE certificate | ||||

| Wetted parts treatment |

/G1 | Ungrease treatment | |||

| /G2 | Electropolishing treatment | ||||